| Calcareous materials | Argillaceous materials | ||

|---|---|---|---|

| Calcium | Silicon | Aluminium | Iron |

| Limestone | Clay | Clay | Clay |

| Marl | Marl | Shale | Iron ore |

| Calcite | Sand | Fly ash | Mill scale |

| Aragonite | Shale | Aluminium ore refuse | Shale |

| Shale | Fly ash | Blast furnace dust | |

| Sea shells | Rice hull ash | ||

| Cement kiln dust etc | Slag | ||

Cement manufacturing is an energy and resource intensive process. It involves closely controlled chemical reactions between calcium silicate minerals at high temperatures of above 1400 degree Celsius. In this process, chemical bonds of key raw materials – limestone, shell, chalk, sand, clays, alumina, iron oxide, etc. – are broken down inside the kiln and recombined into an intermediate compound called clinker, ranging between sizes of 1 mm to 25 mm nodules. The clinker material is further ground into a fine powder and mixed with gypsum to produce cement. Several blended versions of cement are prepared with varying strength, durability, settling time and other specialised properties by adding admixtures, pozzolanic materials, and other additives. Typical raw materials used in cement manufacturing can be categorised under calcareous materials and argillaceous materials Tables.

The physical properties of cement are based on the following

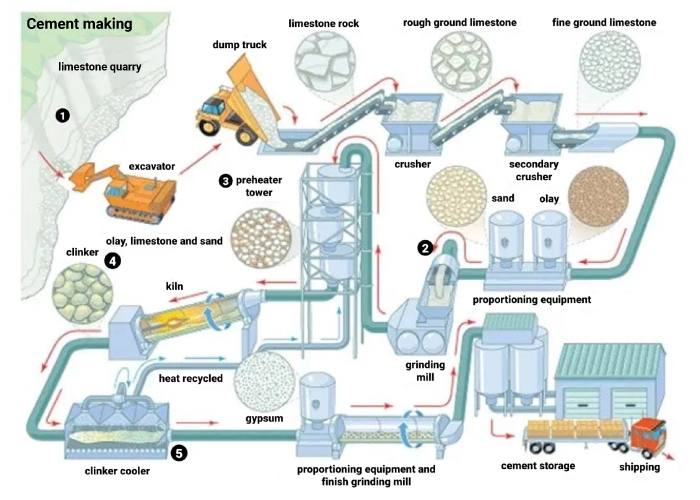

A schematic diagram of cement manufacturing process is depicted by Figure

Mining is the first and foremost step to ensure availability of raw material for cement manufacturing. Limestone and clay materials are natural resources mined out following basic steps:

The method of removing overburden to extract the material depends on a number of factors, including strength and hardness of overburden rock, thickness of the layer, haulage distance, load bearing capacity and susceptibility to weathering. For hard surfaces, drilling and controlled blasting techniques are generally preferred to loosen the stratum and open it for extracting the raw limestone. Surface miners, which are relatively much more environmentally friendly equipment, are becoming a popular choice among mining companies, especially where the surface is less hard. The mined limestone boulders are then loaded onto either rail mounted dumpers, rubber tired vehicles, belt conveyors, wheel loaders etc using excavators, hydraulic excavators, wheel loaders etc.3

The mined raw minerals are crushed in two phases, namely, primary crushing and secondary crushing. The primary crushers such as jaw crushers, gyratory crushers, cone crushers, crushing rolls etc., crushes coarser materials into smaller chunks of size 5 to 8 inches. The secondary crushers mainly hammer crushers, hammer mills, impact crushers, crush the chunks further into sizes between ¾ to 1 inch.4

This raw material mix is fed onto a conveyor belt and passes through a bulk material analyser. A raw material stockpile is created at the plant site using a stacker machine, which receives the crushed minerals from the incoming belt conveyor. A reclaimer machine placed at the other end of the stockpile removes the material in layers in small thicknesses. These are subsequently put onto hoppers and bins through belt conveyors.5

The quantitative proportion of the minerals in the raw mix is modulated at the raw material preparation station to provide the desired chemical and mineralogical composition of the clinker. The chemical composition of the raw materials determines the proportion of raw mix using parameters like lime saturation factor, silica modulus, alumina modulus etc. of the manufactured clinker.6

The prepared raw mix is fed first to a grinding mill (ball mill, tube mill, compound mill etc.), which crushes the limestone into a fine powder. Drying, grinding and mixing takes place simultaneously. For driving the drying process, hot gas from clinker burning unit is passed into it. Separators in the mill use the gases and mechanical force to separate fine particles from the coarse particles. The coarse output returns to the mill for regrinding. The exiting gas contains fine materials and goes to the gas cleaning unit. The fine raw meal is conveyed to the air slide via screw conveyor and then moved into a homogenising silo.7

The homogenising silo has a dual role of blending and storing. Blending is performed by mixing the raw meal using compressed air to get a uniform chemical composition and meal fineness after which the homogenised raw meal is stored in the silo. Raw meal extracted is then fed to the top of the preheater via an air lift for pyro processing. The raw meal is heated to the required temperature to produce the desired clinker compounds in a way that is economical and also increases productivity in the preheater and kiln. The pyro processing unit consists of following:

The raw feed goes to a preheater having a fire column with progressively increasing temperature before moving into a precalciner and rotary kiln. The cyclone preheater kiln could operate between one to six stages with increased fuel efficiency being achieved with each additional stage. Each preheater stage consists of a gas riser duct and a collection cyclone. The raw meal is led in to the riser duct of the first stage cyclone.

The high temperature exhaust gases from the rotary kiln move up through the gas riser ducts of the preheater, and the swirl created by the cyclone column and the central dip tube separates the feed from the gas. While the gases move up the preheater through the dip tube, the feed moves down to the next stage. The purpose of the preheater is to reduce the load on the rotary kiln. At the base of the preheater tower is the precalciner system, which is added to increase thermal efficiency and productivity gains. It reduces the thermal load on the kiln and increases its life. The feed is then sent to the calciner and rotary kiln for additional heating and processing.

The kiln feed is calcined gradually as temperature progressively increases from 600 to 1,000 degree Celsius. Calcination of CaCO3 is a highly energy intensive reaction. The rotary kiln has a number of zones, namely, a calcining zone, a heating zone, liquid/burning zone, a sintering zone and a cooling zone. Once partial calcination is achieved, these are subsequently completely calcined in a rotary kiln and heated to approximately 1,400 degrees Celsius in the sintering zone of the kiln.

CaCO3 → CaO + CO2

Nodulisation of clinker starts in the burning zone itself where temperature of 1,300 to 1,350 degree Celsius is achieved. Clinker components C3A, C4AF, C2S, and C3S are formed. The hot semisolid limestone after passing through the rotary kiln is subsequently cooled. The hot clinker discharge from the kiln drops onto a cooler where it is cooled to approximately 120 degrees Celsius. Planetary coolers, rotary coolers, shaft coolers, grate coolers or eta coolers may be used for cooling of the clinker. The cooled clinker is discharged from the cooler into the pan conveyor and is then stored in the main and reject clinker silos from where it is either transported using roads/ railways/ inland waterways or it is carried to the cement mill for manufacturing cement.

Varieties of cement is prepared by mixing clinker with the other requisite materials in the cement mill. For example, clinker and gypsum are mixed for Ordinary Portland Cement, fly ash for Portland Pozzolana Cement, and slag for slag cement. These are extracted from their respective hoppers and fed to the cement mills.

Clinker is fed into the cement mill - which has two chambers - along with other materials (fly ash, slag, gypsum) as per the variety of the cement, which need to be manufactured. For instance, if Portland Pozzolana Cement (PPC) is to be manufactured then lime, fly ash and gypsum are added in the following approximate proportions. Lime: 60-65%, fly ash: 15-35% and gypsum: upto 3% depending upon requirements.

The two chambers have a certain quantity of ball charge of different sizes. The ball mill grinds the clinker and the raw material mixing them well to manufacture cement. The final discharge from the mill is fed into a bucket elevator, which takes the material to a separator. Here the material is separated into a fine product, which is sent to concrete silos for storage and subsequent packaging. The coarse product which is sent to the mill inlet for regrinding.

Finally, manufactured cement typically gets packed into 50 kg size bags in an automated system and dispatched to the market. Packing machines are of two types, namely, stationary and rotary packer. The main elements used in the packing line are:

The bags are then mechanically sealed and loaded onto conveyors, which are carried for loading and dispatch. For bulk transport, the cement or clinker is directly loaded into bulker wagons or bulker trucks for transportation using rail and road respectively.

The cement bags are loaded onto the wagons using a cement autoloader machine. These machines have multiple telescopic, retractable and hinged conveyor belts, which allow for proper movement and loading. The end of the machine is controlled manually by labour, which loads the cement bags onto the wagon.

Similarly, the Cement bags are loaded onto trucks through conveyor belts, which move bags directly from the packaging unit to the loading area. Bulk carriers are used to supply fly ash to the plant. The cement or clinker is then transported to the intended distribution center/warehouse where it is stored for supply to end consumers.