Cement is the most widely used building material that has bettered almost every structure in the world. It plays an extremely important role in social and economic development and recognised as a core sector in India. Very few people would know that cement is derived from naturally sourced mineral limestone that gets physically mined and chemically processed with other materials in high temperature kilns. The result is a function of chemically controlled reactions between various ingredients to produce clinker, which is ground to make cement.

The critical dependence of cement making over the sustained availability of limestone indicates that minerals are indispensable for modern day living. Every object, as tiny as microprocessor chips to tall concrete buildings, is essentially dependent on raw minerals, primarily harnessed through mining activities.

Mining has played a very crucial role in the advancement of civilisations. Globally, the mineral wealth is finite and, therefore, responsible mining practices are inevitable for meeting future needs. The Indian Cement Industry, well recognised for its energy and resource efficient operations, has been a frontrunner in making use of advanced technology and sustainable business practices. Responsible resource management has been embedded across its value chain, well beyond mining practices alone. Despite increasingly high use of alternative resources by way of blended cement making, limestone remains the mainstay for cement manufacturing.

This in focus series aims to feature prominent best practices followed by the Indian Cement Industry towards responsible mining of limestone mineral.

Limestone is the chief raw material behind the making of cement. It is mined from natural rocks through mechanical excavation generally involving drilling and blasting techniques. The extracted boulders of stone get hauled from inside the mines with large dumpers and taken to the crushing and screening area. The average depth of limestone quarries ranges between 25 m to 50 m.1 Management of the overburden material is an important task taking into account geographical, topological and morphological variations.

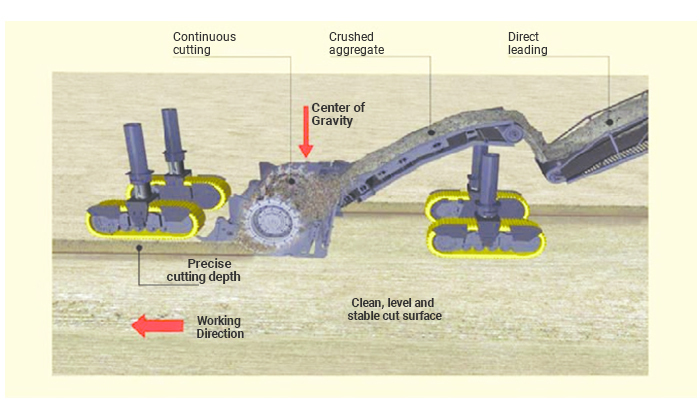

Surface miners are specially designed equipment that eliminate the requirement of drilling and blasting for the excavation of various minerals. This technique is workable for soft to moderately hard limestone and it also helps avoid primary crushing of the mined out material. Compared to any conventional mining practice, the eco-friendly operation of Surface miners results in a significant reduction in vibration, noise and dust development. Gujarat Ambuja Cement (now Ambuja Cements Ltd., a part of Holcim Group) introduced the Surface Miners equipment in India in 1995 for one of their limestone deposits. Since then, it has become popular and adopted across Indian cement companies.2

Surface miners are hydraulically controlled machines that are specially designed to cut, crush and load the material simultaneously, as illustrated in Figure. This brings forth a continuous mining experience. Whilst it cuts the material into the desired size, it can also make use of a conveyer belt system thereby reducing the requirement of heavy dumper vehicles for haulage of mined out material. Surface miners create a closed chamber around the area under excavation and suppress the dust through water spraying. The water sprayed also reduces the wear and tear of cutting tools while keeping them cool and sharp for efficient operations. The wet material also poses the least risk of fugitive emissions during its transportation from the mining pit.3

Surface miners can also be used for the selective mining of thin seams resulting in better control over the product grade. Sometimes for deeper mining of minerals, a requirement of the larger operating surface area is not possible due to limitations posed by nearby habitations; surface mining allows higher bench slope due to elimination of blasting requirements and make mining possible without compromising the safety and environmental factors.

The selection of surface miner machines also depends upon the type and hardness of material under excavation. For instance, a surface miner suitable for limestone might not be suitable for the overburden material and mine planning requires appropriate face planning for optimal use of such machines. Choice of Surface miner equipment is limited by rockmass cuttability classification of the mineral bearing stratum. It is generally not suitable where the compressive strength of the surface is higher than 120 MPa.4

It is undoubtedly a popular choice for opencast mining operations and is largely been adopted by the Indian cement companies keeping in view a safe and responsible mining practice.